our approach aimed at maximizing productivity & efficiency.

Co-Founder, Atlantic Metal

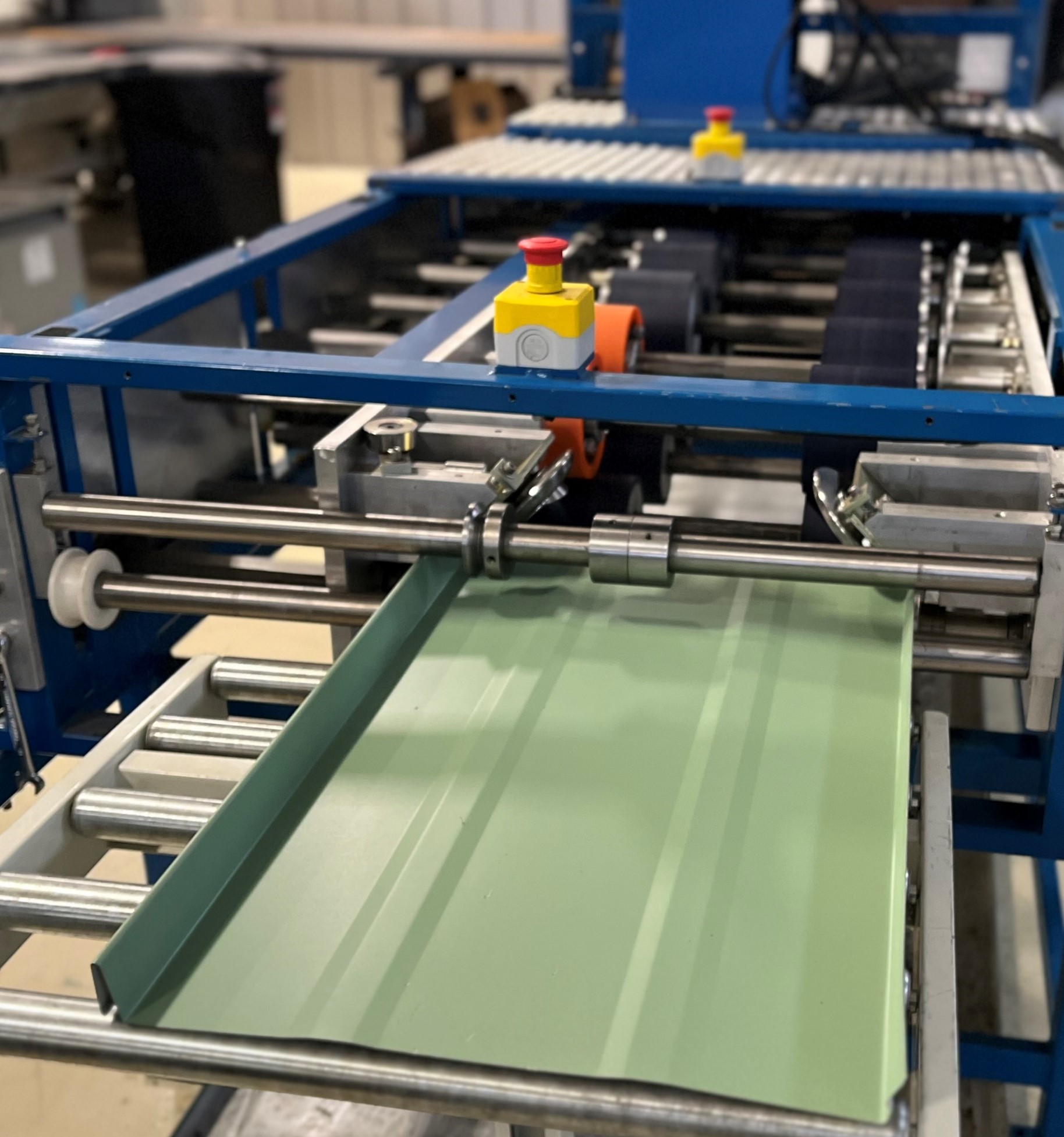

Metal Double deck Roll Forming Machine

The roll forming machine forces the material through a series of mated tool dies to achieve a uniform shape. Each step of the operation bends the workpiece little by little until it reaches the desired shape.

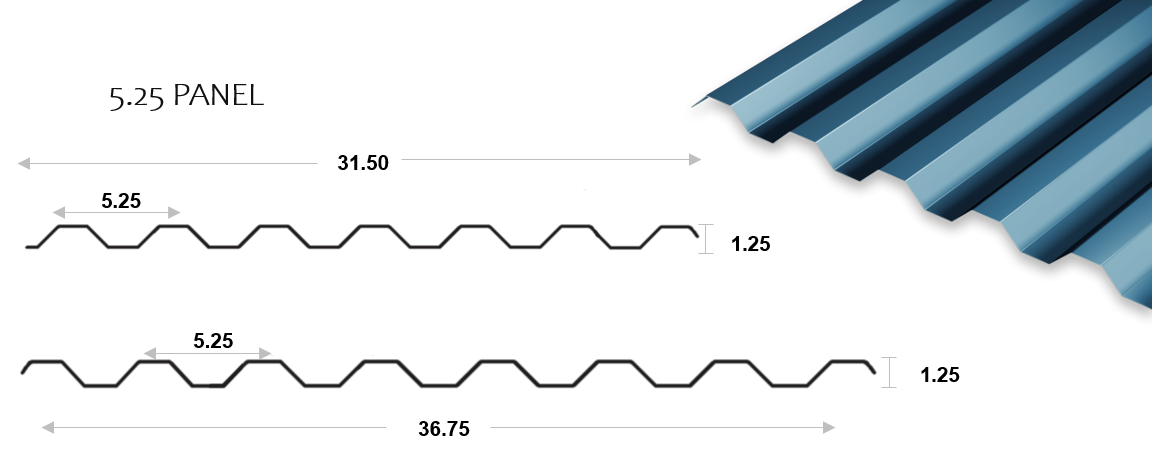

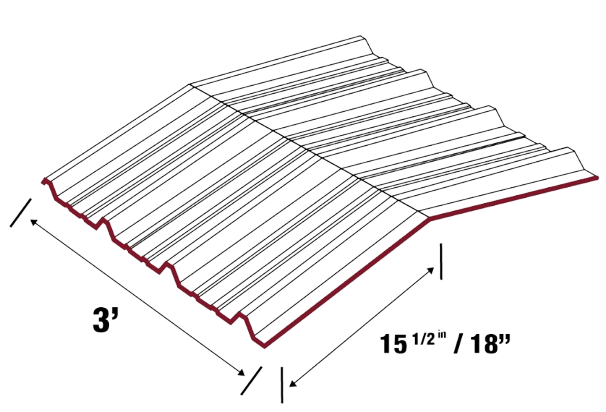

5.25 Panel

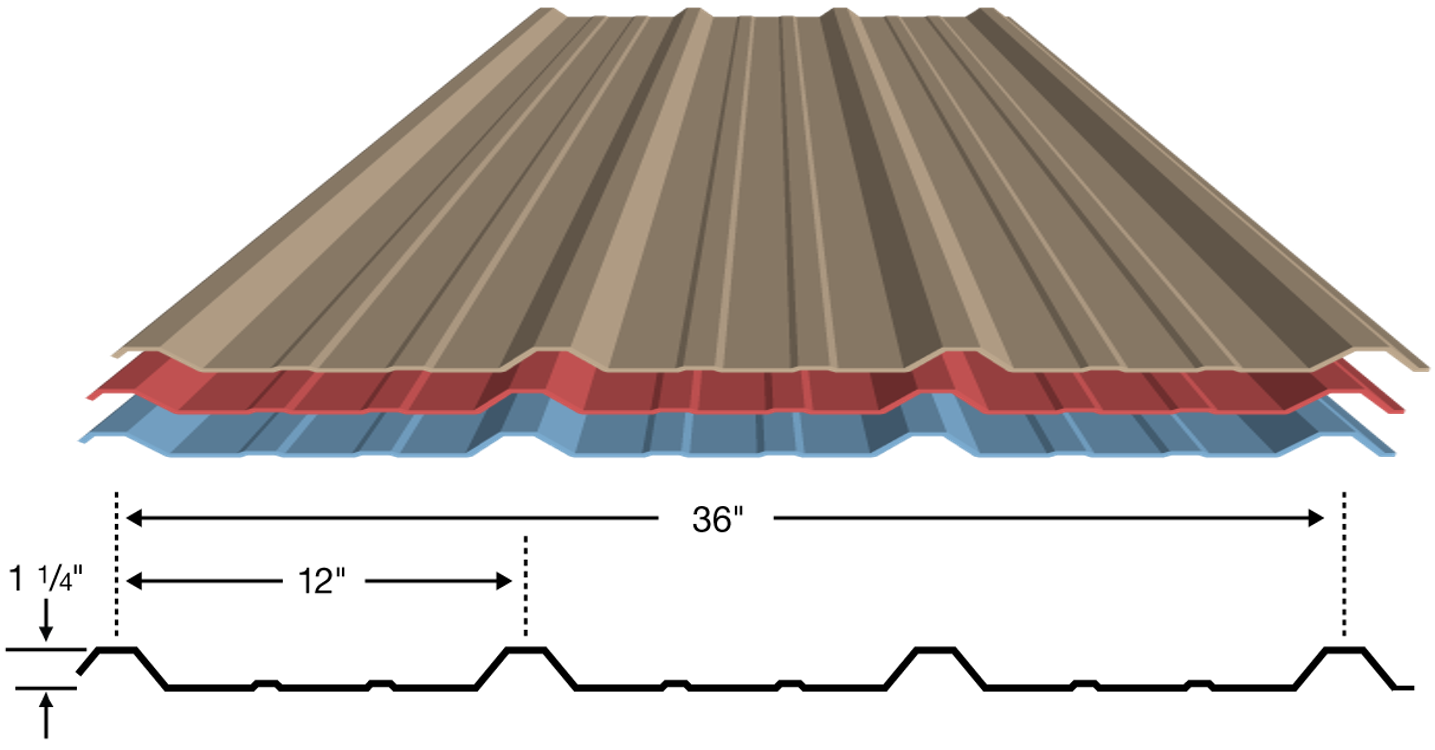

PBR Panel

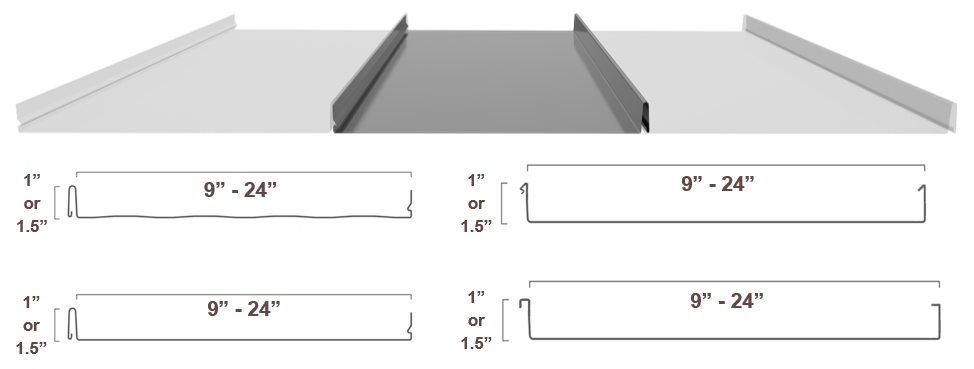

Standing Seam Panformer

“Multi-Profile” capable piece of machinery forming 7 different profiles in total. From Snap Lock styles to true Board and Batten and Bermuda Roof profiles. The versatility is built into the design of the machine but most importantly the changeover time is anywhere from 15 minutes to 1 hour.

4 Panels profiles

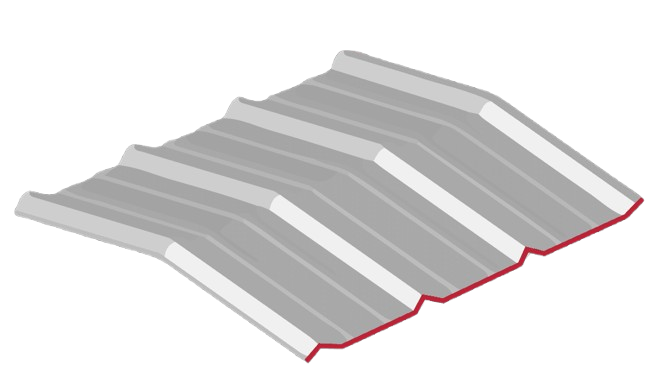

Interlocking Wall/Soffit Panel Machine

1″ Commercial Flush Wall/Soffit Panel. Complete with hydraulic drive and front hydraulic scissors shear, adjustable panel width of 10″ to 24″.

Wall & Soffit Panel

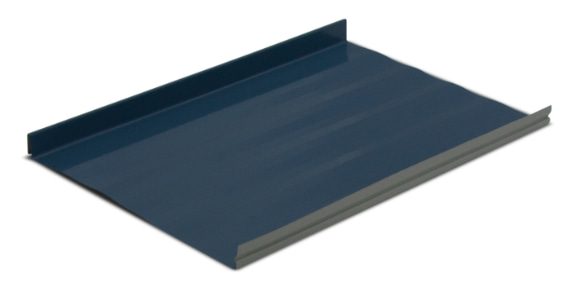

Die Formed Ridge Cap

Die formed ridge cap will match the profile of the metal roofing panel. It’s difficult to install and both ends of the ridge need to line up perfectly or it will not nest. It’s not recommended for roofs with a pitch that’s greater than 6″ in 12″

PBR Panel

Roll Forming

Operation bends the workpiece little by little until it reaches the desired shape.

certified

Roll forming is a highly efficient process, capable of producing long, complex shapes quickly.

Roll Forming Highlights

- Machines for roof & wall profiles

- High productivity

- Up to 50′ long