our approach aimed at maximizing productivity & efficiency.

Co-Founder, Atlantic Metal

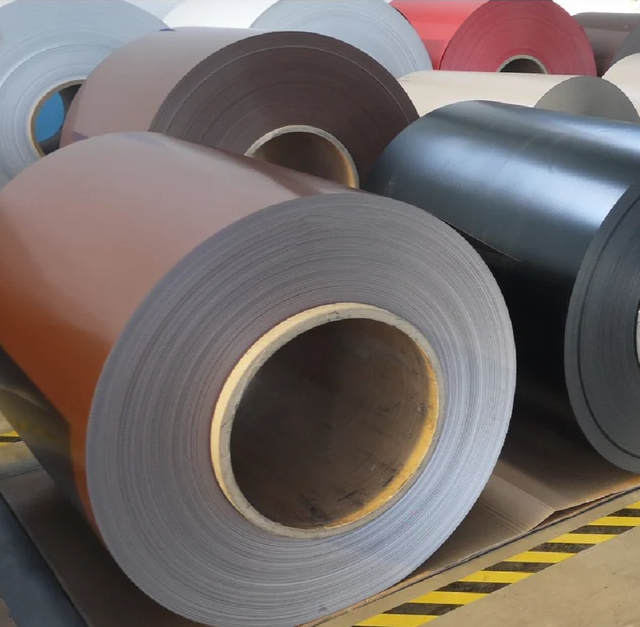

Coil: Slitting | brake by weight | recoiling

The heart of metal coil processing lies in transforming large coils of metal into manageable, usable pieces. This process includes cutting the metal to the desired length, slitting it into narrower coils

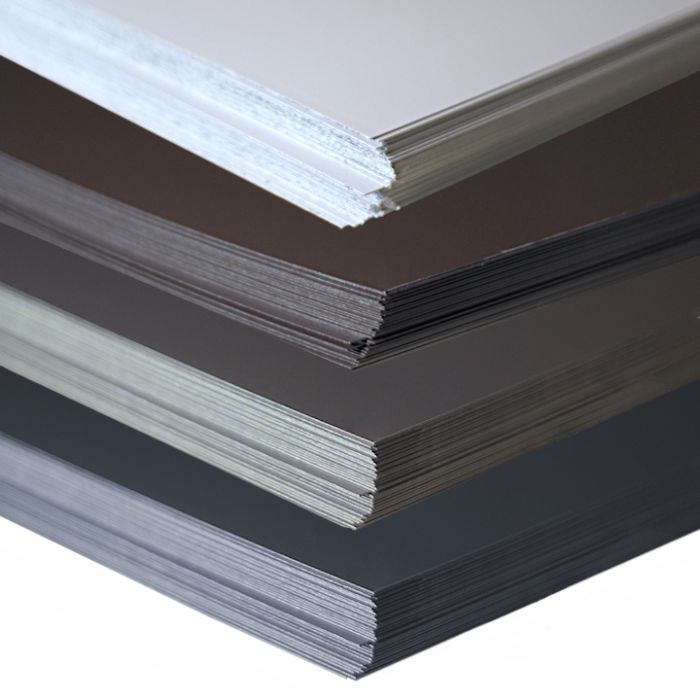

From Coil to Sheets

The process of transforming a steel coil into sheets involves cutting and potentially altering the width of the continuous strip of steel.

Film Applicator

Thanks to support rollers and rubberized feed rollers, the film is pressed onto the sheet metal without the risk of bubbles or wrinkles.

Coil processing

Ccan be done through processes like cut-to-length, slitting, or blanking, depending on the desired sheet size and edge finish.

certified

ASTM and PSTC standards and methods tested

Coil Processing Line

- meets the greatest demands on efficiency and ergonomics

- High productivity

- Width sheets – 42.75″ or 48″