our approach aimed at maximizing productivity & efficiency.

Gregory Ageyev

Co-Founder, Atlantic Metal

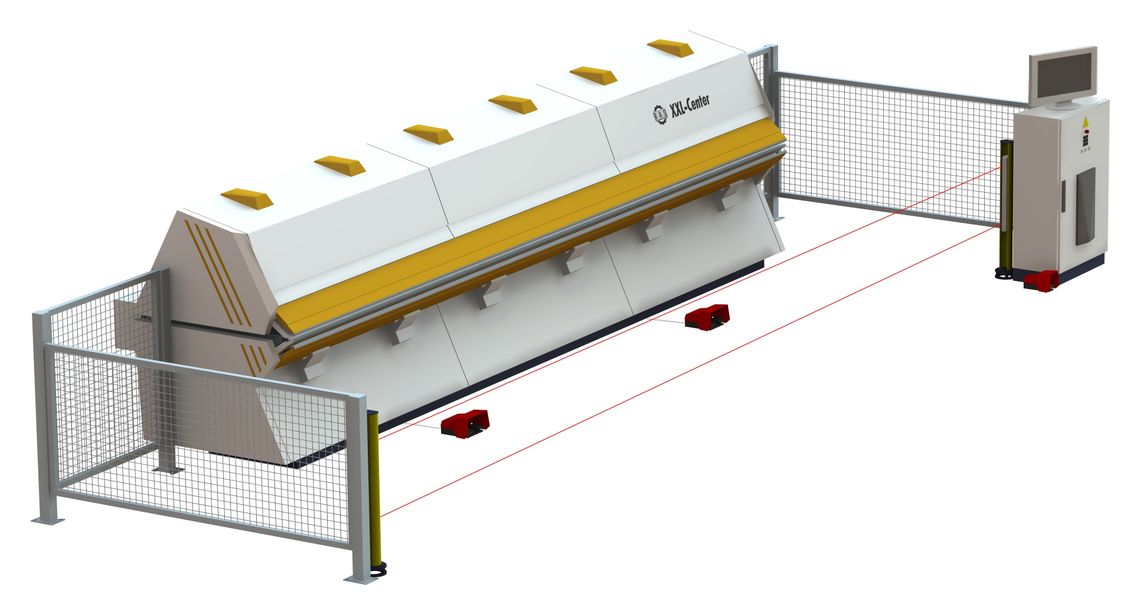

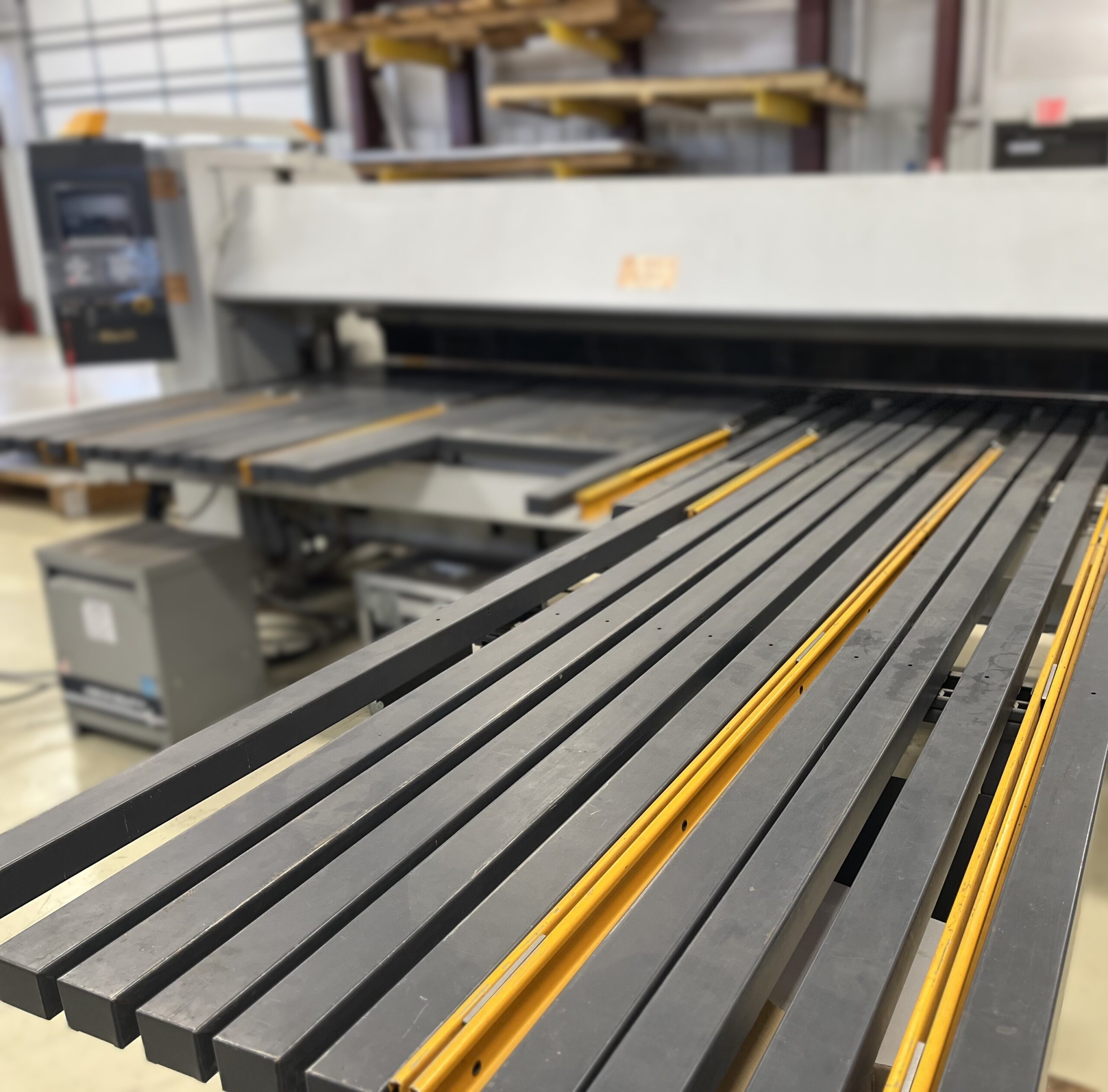

XXL-Center

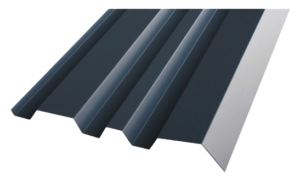

Are you an architect that wants a custom metal panel for your project? Do you need to match an existing metal panel that’s no longer made? If you provide us a line drawing of the panel we can make it for you.

If You Draw It We Can Bend It

Bending complex parts

FLEXIbend 73.30

CIDAN MSR 31

RAS XXL-Center

Bending up and down. Large free spaces for maximum part design flexibility

RAS certified

RAS machines are designed for increased precision and efficiency. 30 years in Business

XXL-Center Highlights

- Machine for roof & wall profiles

- High productivity

- Up to 21′ long